Imagine a common scene in a solar module factory: the automated stringer, a marvel of precision, suddenly stops. An operator rushes over to find a shattered solar cell, grinding the line to a halt. The immediate assumption is often a mechanical issue or operator error. But what if the problem didn’t start on the line? What if the cell was already broken—invisibly—before it ever reached the machine?

This scenario is far more common than you might think. The culprit is often a pre-existing microcrack, a tiny fracture induced during cell manufacturing or shipping. These defects are a ticking time bomb. And with the industry’s shift towards more advanced (and sensitive) cell technologies like TOPCon, catching them early isn’t just a good idea—it’s essential for survival.

THE HIDDEN COST OF A SINGLE CRACKED CELL

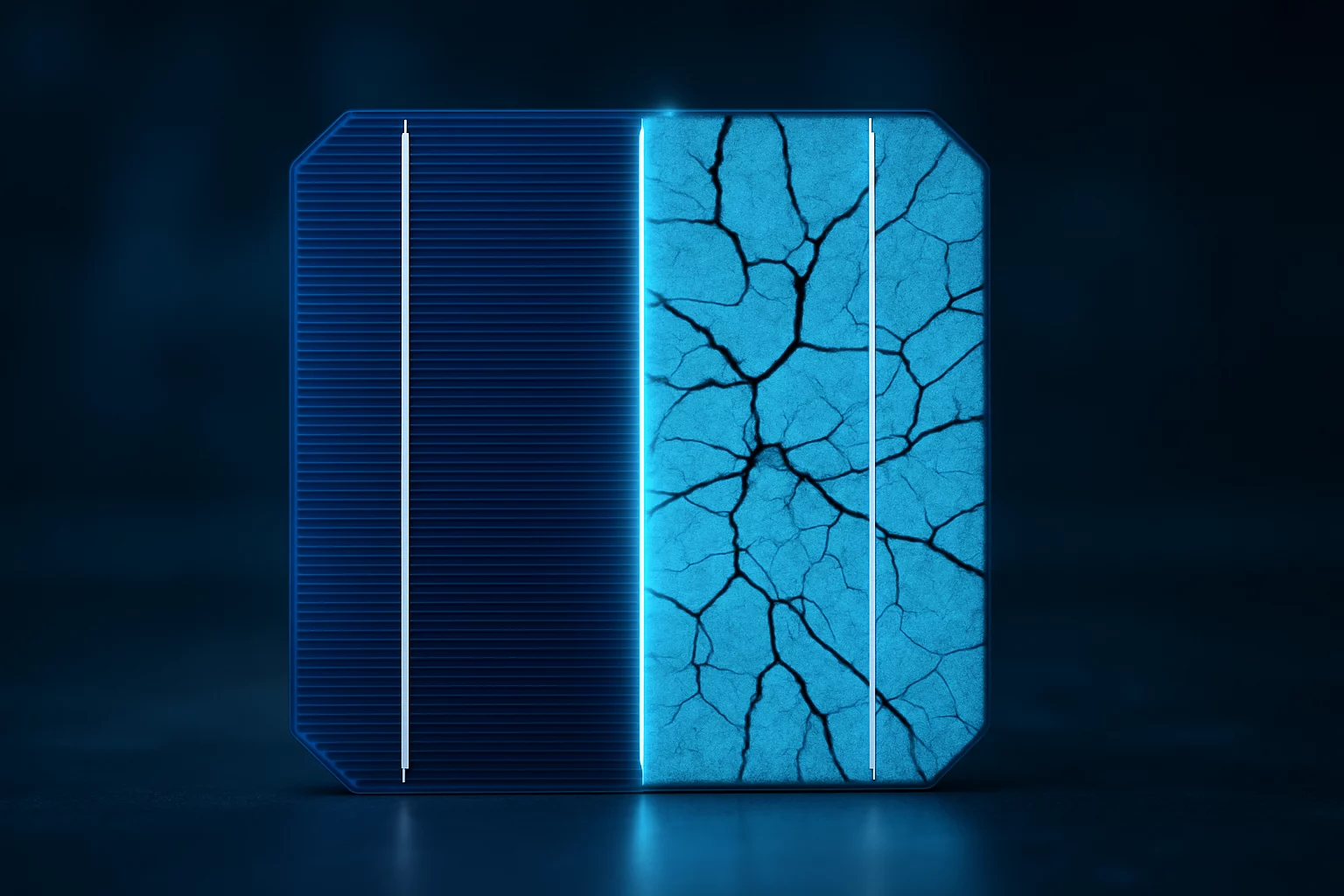

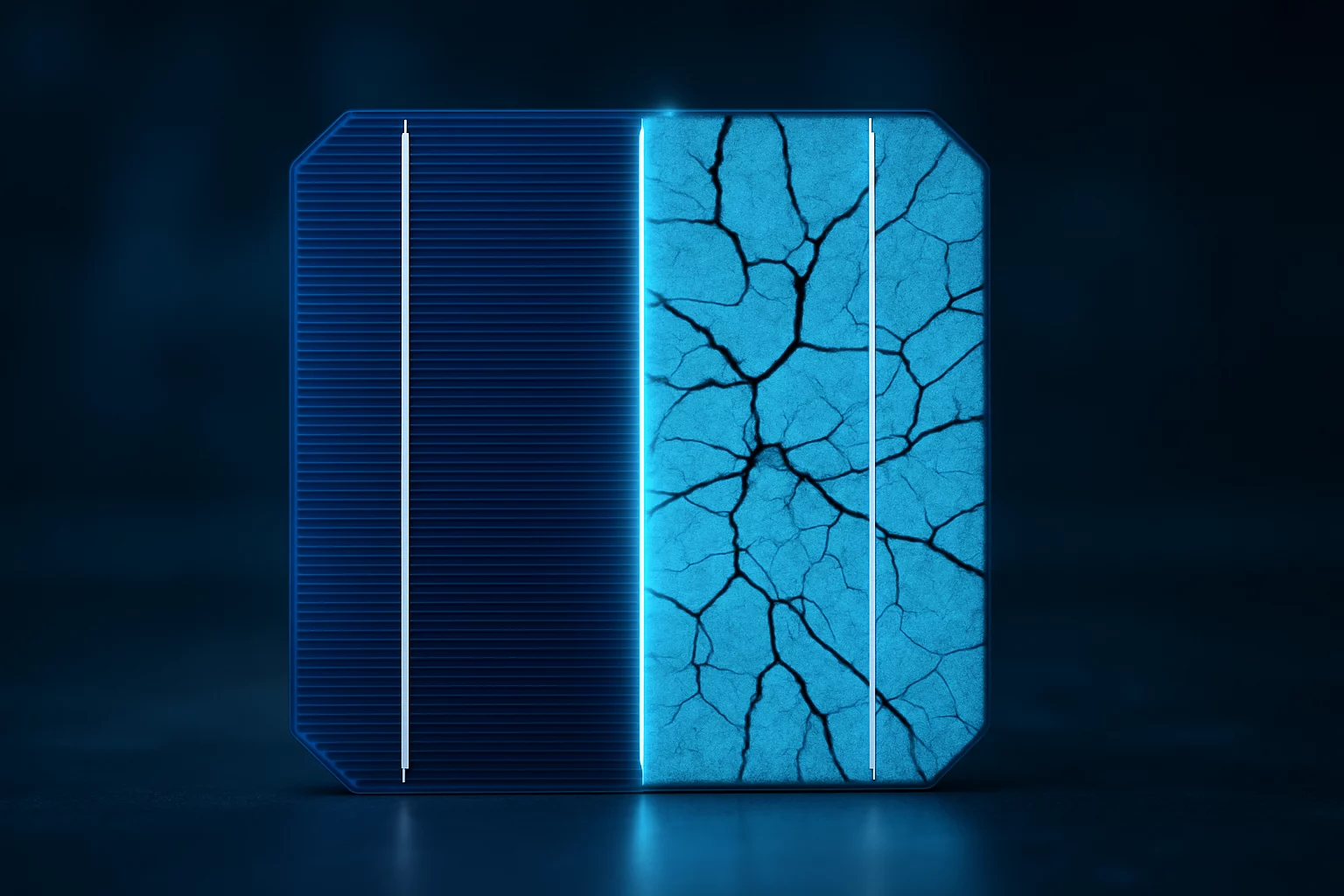

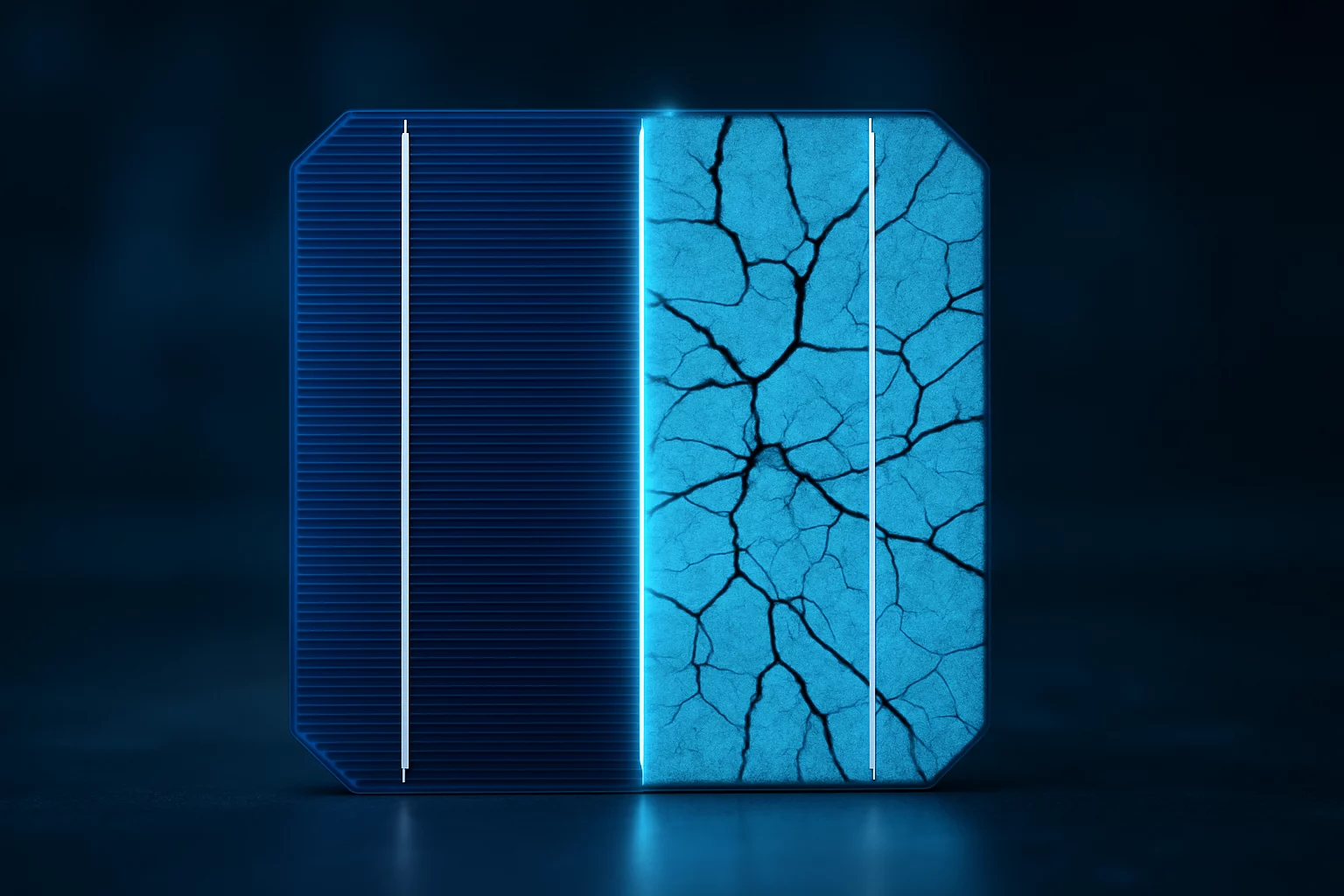

At first glance, a perfect-looking solar cell promises efficiency and power. But lurking beneath the surface, microcracks can tell a different story. These fractures, often invisible to the naked eye, act like roadblocks for electrons, creating dead zones in the cell.

The impact is significant. Research shows that microcracks can reduce module power by up to 3%. Over the 25-year lifespan of a solar panel, that seemingly small loss adds up to a substantial drop in energy generation and revenue. Worse yet, these cracks are weak points that can expand under thermal and mechanical stress once the module is installed, leading to premature failure.

WHY VISUAL INSPECTION JUST ISN’T ENOUGH

For years, the standard for incoming quality control has been a simple visual check. An operator holds a cell up to the light, looking for chips, discoloration, or obvious breaks. While this method can catch catastrophic damage, it completely misses the microscopic fractures that pose the greatest long-term risk.

A cell can look flawless but be riddled with internal defects that will only reveal themselves under operational stress or during the high-pressure lamination process.

What appears perfect on the surface can be severely compromised internally. Relying on visual inspection alone is like proofreading a document by only looking at the pictures. You’re missing the most important information.

A NEW CHALLENGE: THE RISE OF TOPCON TECHNOLOGY

The solar industry is rapidly adopting Tunnel Oxide Passivated Contact (TOPCon) cells for their superior efficiency. But this advanced performance comes with a trade-off. According to industry analysis, because of their thinner structure and full-area rear contact, TOPCon cells are more susceptible to handling-induced stress and microcracks compared to PERC.

Their delicate nature means every step—from the supplier’s factory to your production line—is a potential source of damage. Subtle vibrations in a shipping container or a minor jostle during unpacking can be enough to create a network of hidden cracks. If these cells enter your stringer, you’re not just risking a single cell’s breakage; you’re compromising the integrity of the entire module.

THE POWER OF SEEING THE INVISIBLE: ELECTROLUMINESCENCE (EL) EXPLAINED

So, how do you find a problem you can’t see? The answer is electroluminescence, or EL testing.

Think of EL as an X-ray for solar cells. The process is simple yet powerful: a small electrical current is passed through the cell, causing it to emit light in the near-infrared spectrum. A special camera then captures this light. Healthy, efficient areas of the cell shine brightly, while defective areas—like microcracks, finger interruptions, or inactive zones—appear dark.

EL imaging instantly reveals the true internal quality of the cell, making the invisible visible.

This high-resolution view provides an undeniable quality fingerprint for every cell, allowing you to identify and quarantine damaged goods before they contaminate your production process.

SHIFTING LEFT: THE LOGIC OF INCOMING QUALITY CONTROL

The most effective way to solve a problem is to prevent it from happening in the first place. This is the principle behind „shifting left“—moving quality checks to the earliest possible point in the process. For solar module manufacturing, this means inspecting cells upon arrival, not at the stringer.

The data backs this up emphatically. A recent analysis found that over 50% of cell breakages in production are linked to pre-existing, undetected microcracks. By waiting until the stringing stage to find a defect, you’ve already wasted time, energy, and resources on a faulty component.

„The moment a cracked cell enters the stringer, you’ve already lost. You’re either building a future failure into your module or stopping the line to fix a problem that could have been caught hours earlier. High-res EL at the incoming stage isn’t a luxury; it’s fundamental process control.“ – Patrick Thoma, PV Process Specialist.

Implementing a robust incoming QC program using EL testing delivers three key advantages:

- Reduced Production Downtime: By weeding out cracked cells early, you drastically reduce mid-process breakages at the stringer, improving throughput and overall equipment effectiveness (OEE).

- Improved Module Reliability: You ensure that only high-quality, defect-free cells are used in your final product, a fundamental step for successful solar module prototyping and long-term bankability.

- Data-Driven Supplier Management: EL images provide objective, undeniable proof of a supplier’s cell quality. This data empowers you to have constructive conversations about handling, packaging, and shipping procedures, leading to better quality over time.

PUTTING IT INTO PRACTICE: A PROACTIVE APPROACH

Implementing incoming EL inspection doesn’t require testing every single cell. A statistically significant sampling plan—testing a percentage of cells from each incoming batch—can provide a clear picture of the overall quality and flag any problematic shipments.

For companies without the internal equipment or expertise, this critical analysis can be performed at specialized facilities. Accessing a dedicated R&D production line allows developers and manufacturers to conduct advanced diagnostics, including incoming cell quality checks, as part of broader material testing and lamination trials. This provides crucial data without the capital investment in specialized equipment.

FREQUENTLY ASKED QUESTIONS (FAQ)

WHAT EXACTLY IS A MICROCRACK?

A microcrack is a tiny fissure or fracture in the silicon wafer of a solar cell. They are often too small to be seen with the naked eye but can significantly impact the cell’s performance and long-term durability.

CAN MICROCRACKS BE REPAIRED?

No, once a microcrack has formed in a cell, it cannot be repaired. The only effective strategy is prevention and early detection to ensure cracked cells are never used in a module.

IS EL TESTING A DESTRUCTIVE PROCESS?

Not at all. EL testing is a non-destructive method that uses a very low current to make the cell illuminate. It does not alter or damage the cell in any way, making it perfect for quality control.

HOW OFTEN SHOULD WE TEST INCOMING CELLS?

This depends on your volume and supplier relationships. A common strategy is to test a sample (e.g., 1-5%) from every new batch or shipment. If a sample shows a high rate of defects, the entire batch can be subjected to further inspection or rejected.

DOES THIS ISSUE ONLY APPLY TO TOPCON CELLS?

While TOPCon cells are more susceptible, microcracks are a potential issue for all crystalline silicon cell technologies, including PERC and HJT. The principle of incoming EL inspection is a best practice for any high-quality module manufacturing operation.

FROM DETECTION TO PREVENTION: YOUR NEXT STEPS

The quality of your finished solar module is determined long before the lamination process begins. It starts with the fundamental quality of the components you allow into your factory.

By shifting from fixing breakages reactively to inspecting materials proactively, you build quality into your process from the very beginning. High-resolution EL testing is no longer a niche diagnostic tool; it is a fundamental pillar of modern, high-efficiency module manufacturing.

Take a moment to review your current quality control process. Are you truly confident in the cells entering your line, or are you hoping for the best? Answering that question honestly is the first step toward building more reliable, powerful, and profitable solar modules.