You’ve sourced the highest-efficiency solar cells, selected premium low-iron glass, and engineered a robust frame. Your module is designed for performance. But what about the unsung hero holding this multi-decade investment together? We’re talking about the encapsulant—the transparent „glue“ that bonds the glass, cells, and backsheet into a single, durable unit.

For years, Ethylene Vinyl Acetate (EVA) has been the industry workhorse. It’s cost-effective and well-understood. But as module technology advances, a newer contender, Polyolefin Elastomer (POE), is gaining ground, promising superior long-term stability.

But how can you be sure this bond will hold up not just on day one, but after 25 years of punishing heat and humidity? The answer lies in a simple but powerful metric: peel strength.

What is a Peel Strength Test, and Why Does It Matter?

Imagine trying to peel a stubborn price sticker off a new product. The force it takes to lift that sticker is essentially what a peel strength test measures. In solar module manufacturing, we perform this test with much more precision to quantify the adhesion between the encapsulant and the glass.

The test, typically measured in Newtons per centimeter (N/cm), tells us exactly how strong the bond is. A high value suggests a robust, reliable connection. A low value warns of potential delamination—a catastrophic failure where layers of the module begin to separate, allowing moisture to seep in and corrode the cells, killing the panel from the inside out.

At PVTestLab, we use a specialized setup to perform this test, pulling the encapsulant from the glass at a controlled angle and speed to get precise, repeatable data.

But simply measuring the force isn’t enough. We also need to understand how it fails.

The Story Behind the Break: Adhesive vs. Cohesive Failure

When a bond gives way during a peel test, it fails in one of two ways—and each tells a different story about your material and process.

-

Adhesive Failure: This is like that price sticker peeling off cleanly. The failure occurs right at the interface between the encapsulant and the glass. This often indicates a problem with the bonding process itself—perhaps the glass surface wasn’t clean, or the lamination parameters weren’t quite right. The bond never truly formed to its full potential.

-

Cohesive Failure: Here, the bond to the glass is so strong that the encapsulant material itself rips apart. You’ll see encapsulant residue left behind on the glass. This is the ideal scenario. It tells you that the adhesion to the glass is stronger than the internal strength of the encapsulant material. You’ve achieved the maximum possible bond for that specific material.

Understanding this distinction is fundamental to diagnosing and optimizing the long-term reliability of a solar module.

The Real Challenge: Adhesion After Years in the Field

A strong bond in a brand-new module is great, but it can be a false sense of security. The real enemy of adhesion is long-term exposure to heat and moisture. To simulate this, we use an environmental chamber for a Damp Heat (DH) test. Samples are subjected to 85°C and 85% relative humidity for 1,000 hours—an industry-standard method for accelerating the aging process.

This is where the true character of an encapsulant is revealed. How does the reliable veteran, EVA, stack up against the promising newcomer, POE, after this punishing test?

A Head-to-Head Comparison: POE vs. EVA Peel Strength

We recently conducted a detailed comparison at PVTestLab to answer this exact question. We laminated both a standard EVA and a high-performance POE to solar glass using industry-standard process parameters optimized for each material, then measured the peel strength before and after a 1,000-hour Damp Heat test.

The results were revealing.

Initial Peel Strength (Before Damp Heat)

- EVA: Showed a respectable initial peel strength of 95 N/cm. The failure mode was mostly cohesive, indicating a solid initial bond was achieved.

- POE: Started even stronger, with an initial peel strength of 115 N/cm, also showing a desirable cohesive failure.

On day one, both materials performed well, with POE having a slight edge. But the story changes completely after simulating years of environmental stress.

Peel Strength After 1,000 Hours of Damp Heat

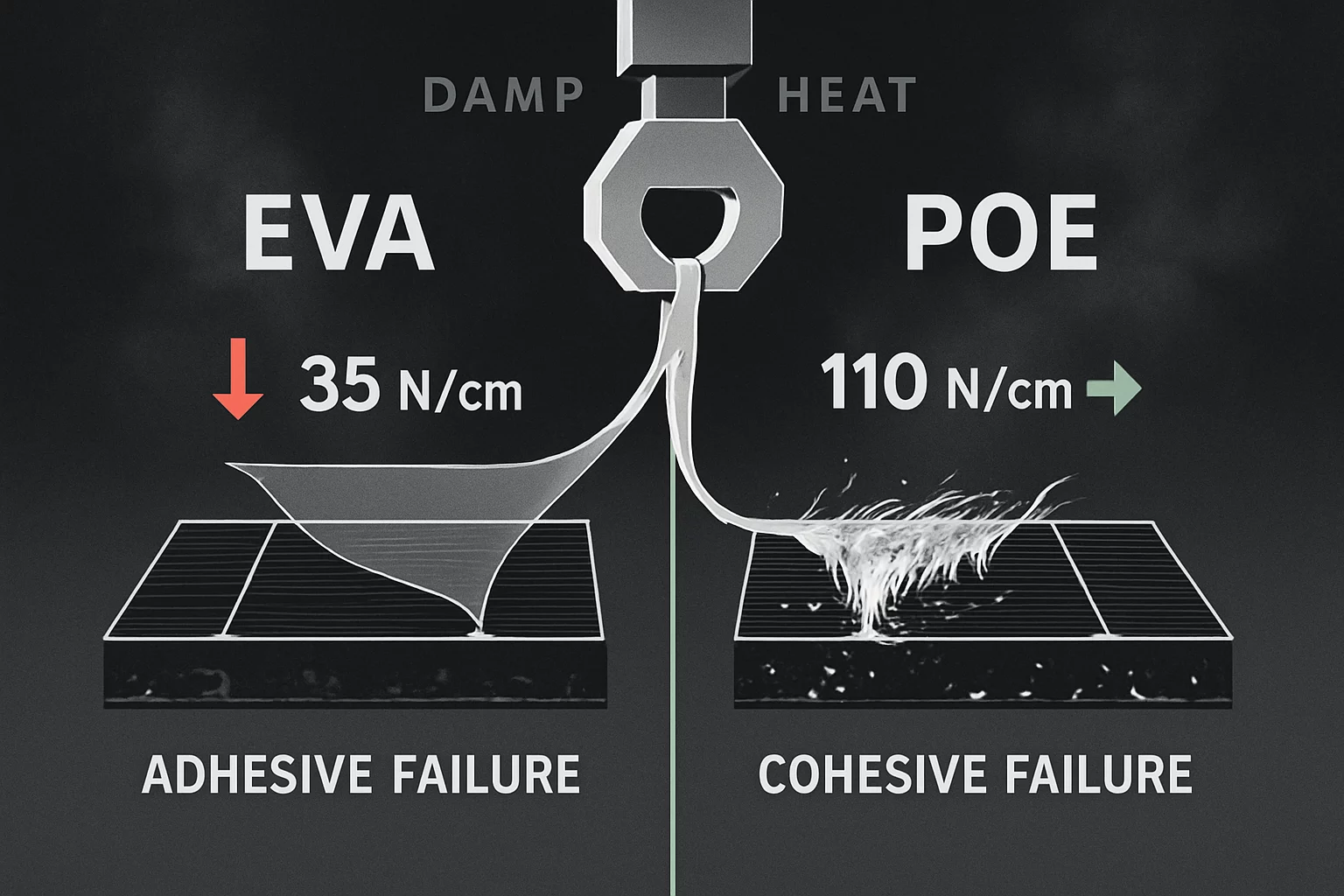

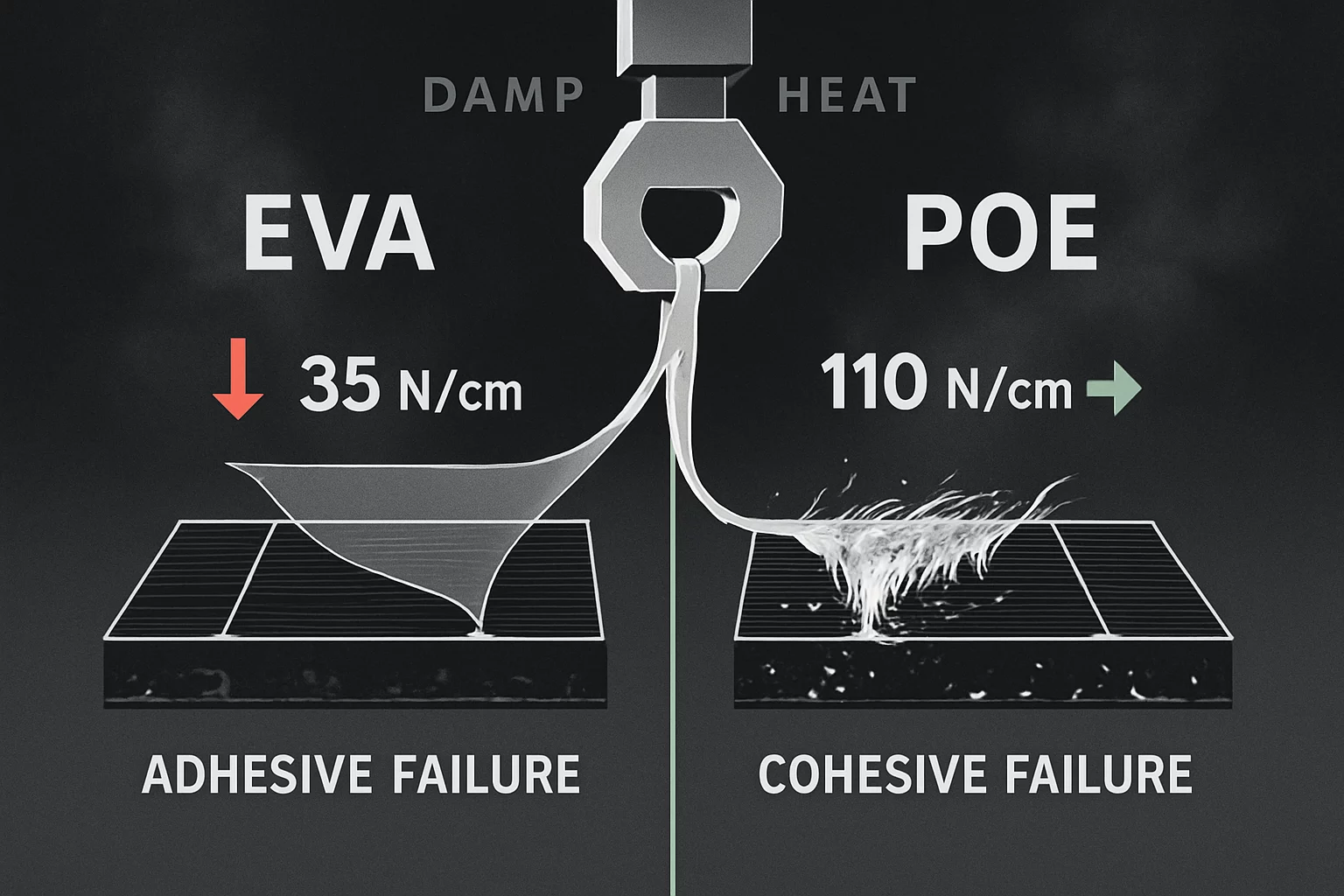

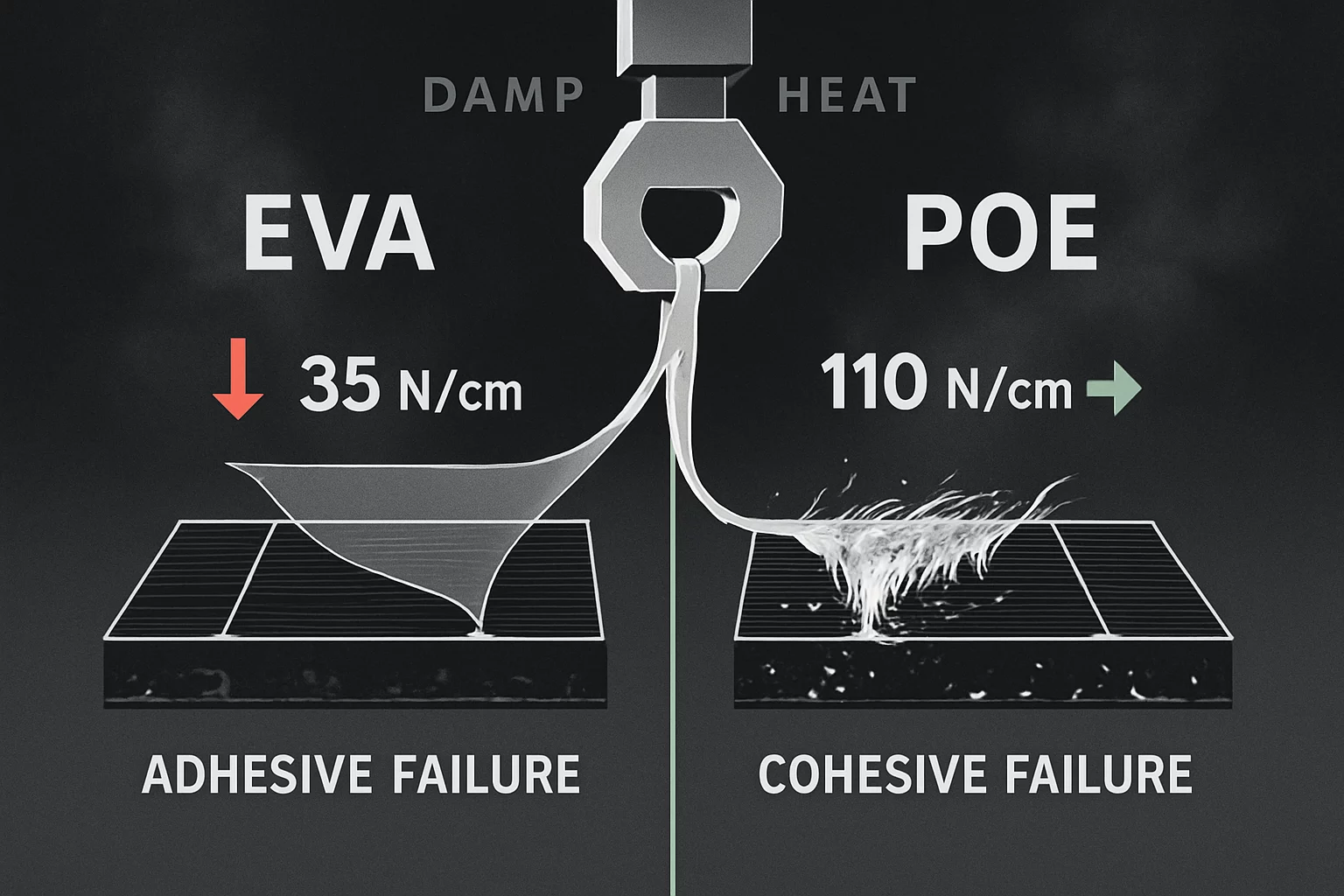

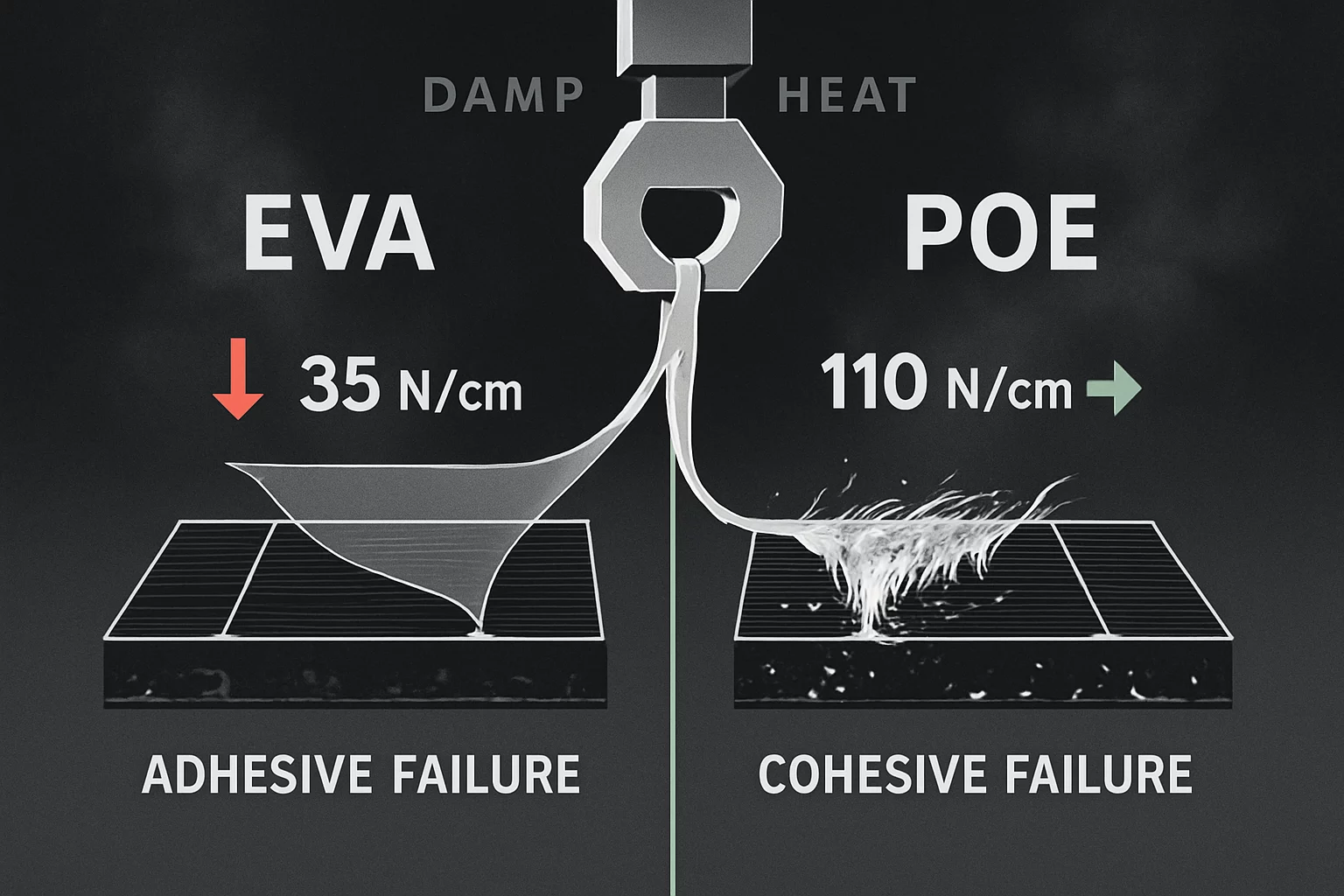

- EVA: The adhesion strength plummeted by over 60%, dropping to just 35 N/cm. Even more concerning, the failure mode shifted from cohesive to 100% adhesive. The bond at the glass interface had chemically degraded, effectively letting go.

- POE: The adhesion remained remarkably stable, measuring 110 N/cm—a negligible drop from its initial value. Crucially, the failure mode remained 100% cohesive, proving the bond to the glass was unshaken by the intense heat and humidity.

„The data is unambiguous,“ notes Patrick Thoma, PV Process Specialist at PVTestLab. „While initial adhesion is important, it’s the retained adhesion after environmental stress that predicts true 25-year performance. In humid, high-temperature environments, the chemical stability of POE’s bond to glass provides a significant reliability advantage over traditional EVA.“

This „aha moment“ is critical for anyone developing a new solar module. The encapsulant that seems perfectly fine in initial quality checks might be the very component that fails a decade down the line—a risk that can be easily mitigated with the right material testing and validation. When building your module, you’re not just assembling parts; you’re creating a system designed to withstand decades of stress. This makes the choice of encapsulant a cornerstone of its long-term bankability. For those in the design phase, exploring different material combinations through solar module prototyping is essential for validating these long-term performance characteristics.

You Can’t Fix a Bad Recipe with Good Cooking: The Role of Lamination

While choosing a superior material like POE is a huge step, it’s not the whole story. Even the right material will fail if the process isn’t right. The lamination cycle—the specific profile of temperature, pressure, and time used to cure the encapsulant—is just as important as the material itself.

- Under-curing: If the temperature is too low or the time too short, the encapsulant won’t cross-link properly, resulting in a weak, unstable bond.

- Over-curing: Too much heat or time can make the material brittle, also compromising its adhesive properties.

Finding the „goldilocks zone“ for your specific combination of materials is key. This requires a systematic approach to process optimization, running trials with slight variations in the solar module lamination process to identify the parameters that deliver the highest and most stable peel strength.

Frequently Asked Questions (FAQ)

- What is considered a „good“ peel strength value for a solar encapsulant?

While there’s no single industry-wide number, most experts agree that a value above 40 N/cm after aging tests is acceptable for reliable long-term performance. However, top-tier modules aim for much higher values (80+ N/cm) to build in a significant safety margin against delamination.

- Why does EVA lose so much adhesion in damp heat?

EVA contains vinyl acetate, which can break down over time in the presence of heat and moisture, producing acetic acid. This acid can then corrode the cell metallization and, more importantly, attack the chemical bonds at the glass-encapsulant interface, leading to adhesive failure. POE is inherently more resistant to this type of hydrolysis.

- If POE is better, why isn’t everyone using it?

Historically, POE has been more expensive and can be more challenging to process than EVA. However, as the price gap narrows and the industry prioritizes long-term reliability for technologies like bifacial and TOPCon modules (which are more sensitive to moisture), POE adoption is rapidly increasing. Making the right choice requires careful consideration of many factors, a process often covered in encapsulant material selection and testing protocols.

- Does the type of glass or backsheet affect peel strength?

Absolutely. Different coatings on the glass or surface treatments on the backsheet can significantly impact how well an encapsulant adheres. This is why it’s crucial to test the entire system of materials you plan to use in production, not just the encapsulant in isolation.

Your Next Step: From Knowledge to Certainty

Understanding the dynamics of peel strength is the key to building a truly durable and reliable solar module. You now see that initial adhesion is only half the picture and that the real test of performance comes after simulating years of harsh environmental stress.

The data shows a clear performance advantage for materials like POE, but it also highlights the critical importance of a dialed-in lamination process. Don’t leave the 25-year performance of your product to chance.

If you’re ready to move from assumptions to data-driven certainty, it’s time to see how your specific materials perform under real-world conditions. Exploring comprehensive PV module testing services provides the validated insights you need to make the right decisions, ensuring your product is built to last.